I-PI (Polyimide) Powder, Rod, Sheet, CNC Design Products

I-Thermosetting polyamides iyaziwa ngokuzinza kwe-thermal, ukuchasana kakuhle kweekhemikhali, iimpawu ezibalaseleyo zoomatshini, kunye nombala o-orenji / otyheli. I-Polyamides edityaniswe negraphite okanye i-glass fiber reinforcements inamandla okuguquguquka ukuya kuthi ga kwi-340 MPa (49,000 psi) kunye nemoduli ye-flexural ye-21,000 MPa (3,000,000 psi). I-Thermoses i-polymer matrix polyamides ibonisa ukuhamba okuphantsi kakhulu kunye namandla aphezulu okuxinana. Ezi propati zigcinwa ngexesha lokusetyenziswa rhoqo ukuya kuma-232 °C (450 °F) kunye nohambo olufutshane, oluphezulu njenge-704 °C (1,299 °F).[11] Iindawo ezibunjiweyo ze-polyimide kunye ne-laminates zinokuxhathisa okuhle kakhulu kobushushu. Amaqondo obushushu aqhelekileyo okusebenza kweendawo ezinjalo kunye nelaminates zisuka kwi-cryogenic ukuya kwezo zingaphezu kwama-260 °C (500 °F). Iipoliamide nazo ngokwendalo ziyakwazi ukumelana nokutsha kwaye azidli ngokuba yimfuneko ukuba zixutywe nezithinteli zomlilo. Uninzi luphethe ukulinganisa kwe-UL ye-VTM-0. I-Polyimide laminates zinamandla okuguquguquka kobomi besiqingatha kwi-249 °C (480 °F) yeeyure ezingama-400.

Iindawo eziqhelekileyo ze-polyimide azichatshazelwa zizinyibilikisi ezisetyenziswa ngokuqhelekileyo kunye ne-oyile - kubandakanywa ii-hydrocarbons, i-esters, i-ethers, i-alcohol kunye ne-ferns. Zikwaxhathisa ii-asidi ezibuthathaka kodwa azikhuthazwa ukuba zisetyenziswe kwiindawo ezine-alkalis okanye i-acids ezingaphiliyo. Ezinye iipolyamides, ezifana ne-CP1 kunye ne-CORIN XLS, ziyanyibilika kwaye zibonisa ukucaca okuphezulu kwe-optical. Iipropati zokunyibilika zibaboleka kwisitshizi kunye nezicelo zokunyanga ubushushu obuphantsi.

Iimpawu zePI

I-PI yipolymer yayo ye-flame retardant, engatshiyo kwiqondo lokushisa eliphezulu

Iimpawu zoomatshini uvakalelo oluphantsi lobushushu

Izinto eziphathekayo zinamandla ombala obalaseleyo, zinokufikelela kwiimfuno ezahlukeneyo zokufanisa umbala

Ukusebenza kakuhle kwe-thermal: Ukushisa okuphezulu kunye nokumelana nokushisa okuphantsi

Ukusebenza kombane okugqwesileyo: Ukufakwa kombane okuphezulu

I-PI Main Application Field

Isetyenziswa kakhulu koomatshini, izixhobo, iinxalenye zemoto, umbane kunye ne-elektroniki, umzila kaloliwe, izixhobo zasekhaya, unxibelelwano, oomatshini belaphu, ezemidlalo kunye neemveliso zolonwabo, imibhobho yeoli, iitanki zamafutha kunye nezinye iimveliso zobunjineli ezichanekileyo.

Izinto zePolyimide zikhaphukhaphu, ziguquguquka, zixhathisa ubushushu kunye neekhemikhali. Ke ngoko, zisetyenziswa kwishishini le-elektroniki kwiintambo eziguquguqukayo kunye nefilimu ekhuselayo kucingo lwemagnethi. Ngokomzekelo, kwikhompyutheni yekhompyutheni, intambo edibanisa ibhodi ye-logic engundoqo kwisiboniso (ekufuneka iguqule rhoqo xa i-laptop ivuliwe okanye ivaliwe) ihlala isiseko se-polyimide kunye nabaqhubi bethusi. Imizekelo yeefilimu ze-polyimide ziquka i-Apical, i-Kapton, i-UPILEX, i-VTEC PI, i-Norton TH kunye ne-Kaptrex.

Ukusetyenziswa okongeziweyo kwe-polyimide resin kufana ne-insulating kunye ne-passivation layer ekwenzeni iisekethe ezidibeneyo kunye ne-MEMS chips. Umaleko we-polyimide unobude obulungileyo bomatshini kunye nokomelela kokuqina, okukwanceda ukuncamathela phakathi kwamaleya e-polyimide okanye phakathi komaleko we-polyimide kunye nomaleko wesinyithi odiphozithiweyo.

| Intsimi | Iimeko zesicelo |

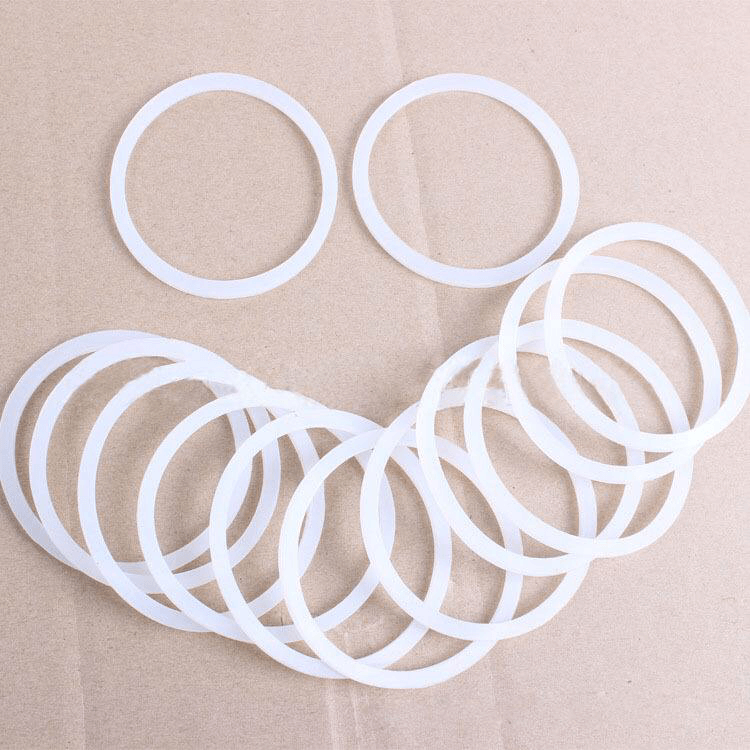

| Icandelo loShishino | Ubushushu obuphezulu obuzithambisayo, i-compressor piston ring, umsesane wokutywina |

| Izincedisi zombane | Iiradiator, ifeni yokupholisa, umqheba wocango, isivalo setanki yamafutha, igrile yokungenisa umoya, isigqubuthelo setanki lamanzi, isiphatho sesibane |

SPLA-3D amaBanga kunye neNkcazelo

| IBanga | Inkcazo |

| I-SPLA-3D101 | Ukusebenza okuphezulu kwePLA. I-PLA yenza ngaphezu kwe-90%. Isiphumo esihle sokushicilela kunye nokuqina okuphezulu. Izibonelelo zizinzile, ukuprintwa okugudileyo kunye neempawu ezibalaseleyo zomatshini. |

| SPLA-3DC102 | I-PLA ithatha i-50-70% kwaye igcwele kwaye igxininiswe. Izibonelelo ezizinzileyo zokwenza, ukuprinta okugudileyo kunye neempawu ezigqwesileyo zoomatshini. |