(1) Impembelelo yemathiriyeli ekrwada

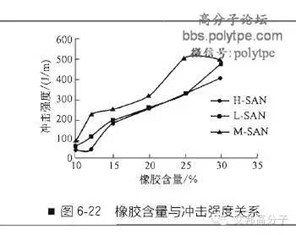

Iimpawu ezahlukeneyo zePC kunye ne-ABS resin blend yealloy inomahluko omkhulu ekusebenzeni. Inokubonwa kwi-Figure 6-22 ukuba umxholo werabha ophezulu uphucula amandla empembelelo ye-PC / ABS inkqubo, kodwa yonakalisa kakhulu ukuziphatha kwe-capacitance phakathi kwezigaba, ngaloo ndlela kuncitshiswe iipropati ezithintekayo ze-alloy. Ke ngoko, ukukhetha i-ABS enomxholo ofanelekileyo werabha ayinakuphucula kuphela amandla empembelelo yomxube, kodwa ikwanyusa amandla ayo okugoba ngokubambisana. Xa i-ABS enomxholo werabha ephantsi isetyenziswa, amandla okugoba e-alloy aya kubonakala ephucula i-synergistic. Ukongezelela, i-acrylonitrile ephezulu, umxholo we-rubber ophantsi kunye ne-molecular weight ABS inokuphucula ukuxhathisa ukushisa kwe-alloy.

(2) Impembelelo ye-PC / ABS ye-blend ratio kwiipropati ze-alloy

Ukuhambelana kunye neempawu zemishini ye-PC / ABS inkqubo yokudibanisa ihambelana ngqo nomxholo wecandelo ngalinye kwinkqubo. Cao Mingan et al. ifumene ii-alloys ezahlukeneyo ze-PC/ABS ezineempawu ezahlukeneyo ngokulungelelanisa umlinganiselo wokudibanisa wePC kunye ne-ABS resin. Iipropati ze-PC/ABS ingxubevange zinobudlelwane bomgca kunye nomxholo we-ABS, kwaye malunga nokuthobela ukudibanisa. Iipropati ezipheleleyo ze-PC/ABS ingxubevange ziphakathi kwe-PC kunye ne-ABS, kwaye amandla empembelelo anempembelelo ye-superadditivity (okt i-synergy effect) kunye nesiphumo sokuchasa kunye nomlinganiselo.

(3) Isiphumo secandelo lesithathu

Ukumelana nokushisa kunye nokuzinza kwe-thermal ye-PC / ABS i-alloy inokuphuculwa ngokudibanisa i-benzothiazole kunye ne-polyimide. I-fluidity ye-alloy ye-PC/ABS inokuphuculwa ngokungongeza izilungiso zokulungisa ezifana ne-ethylene oxide/propylene oxide block copolymer, i-MMA/St copolymer kunye ne-olefin/i-acrylic copolymer yeviniga. Ukongeza, ukuze kuphuculwe amandla adibeneyo emveliso ye-PC/ABS yenaliti yealloyi, i-PMMA, i-SAN, i-SBR, i-acrylic acrylic elastomer, i-low density polyolefin, i-ethylene/i-acrylic iviniga/i-acetic acid, i-ethylene (iviniga) i-copolymer, i-PC/ ibhloko ye-ethylene. okanye i-copolymer yokugxunyekwa kunye nezinye izinto zihlala zongezwa.

(4) Impembelelo yeteknoloji yokucubungula

I-PC kunye nezixhobo zokudibanisa i-ABS zingakhetha kwi-twin screw extruder kunye ne-screw extruder enye ene-static mixer. UJong Han Chun ukholelwa ukuba isiphumo sokuxova ngokuqhubekayo sifanelekile. Ngokubhekiselele kwimodi yokudibanisa, umphumo wokudibanisa okwesibini ungcono. Nangona kunjalo, ngomyalelo wesibini wokudibanisa, inxalenye yezixhobo kufuneka ikhutshwe kabini kwiqondo lokushisa eliphezulu, elinokusetyenziswa kwamandla aphezulu, kulula ukuthotywa kwezinto kunye nokunciphisa iimpawu ze-alloy.

Indlela yokubumba nayo inempembelelo enkulu kwi-morphology kunye nesakhiwo se-PC / ABS alloy. Umzekelo, umfuziselo owenziwe ngokucinezela iplastiki unokugcina ngcono ubume be-microstructure heterogeneous dispersion state eyenziwe ngumxube wealloyi, ngelixa inaliti ibumba, ngesantya esiphezulu sokucheba, imeko yokusasazwa iyatshintsha kwaye ifikelele ekubolekeni ngokugqithisileyo. Ke ngoko, amandla eempembelelo zeesampulu zimbini anomahluko omkhulu, kwaye amandla empembelelo yesampulu yokubumba iphezulu. I-PC emanzini (umxholo wamanzi mkhulu kune-0.03%) kunye nobushushu obuphezulu (ubushushu bungaphezulu kwe-150 ℃) phantsi kokuthotywa lula, ngoko ke kumxube okanye ukubumba phambi komiswe, kufuneka kuthintelwe izithambisi ze-stearic acid ezixutyiweyo, ukuze zingachaphazeli ukusebenza kweemveliso.

Ixesha lokuposa: 02-06-22