Ubushushu bomngundo bubhekisa kubushushu bomphezulu womgodi wokungunda othi udibane nemveliso kwinkqubo yokubumba inaliti. Ngenxa yokuba ichaphazela ngokuthe ngqo izinga lokupholisa kwemveliso kwisigxina sokubumba, esinempembelelo enkulu ekusebenzeni kwangaphakathi kunye nokubonakala komgangatho wemveliso.

1. Impembelelo yobushushu besikhunta kwimbonakalo yeemveliso.

Ubushushu obuphezulu bunokuphucula ubumanzi be-resin, edla ngokwenza umphezulu wemveliso ugudiswe kwaye ubengezele, ngakumbi ukuphucula ubuhle bomphezulu weglasi yeemveliso ze-resin zefiber. Ngexesha elifanayo, likwaphucula amandla kunye nokubonakala komgca we-fusion.

Ngokubhekiselele kwi-etched surface, ukuba ukushisa kwe-mold kuphantsi, kunzima ukuba inyibilike igcwalise ingcambu ye-texture, eyenza ukuba ubuso bemveliso bubonakale bukhazimlayo, kwaye "ukudluliselwa" akukwazi ukufikelela kwi-texture yokwenyani yendawo yokubumba. . Isiphumo esifanelekileyo se-etching sinokufumaneka ngokwandisa ubushushu bokubumba kunye nobushushu bezinto eziphathekayo.

2. Impembelelo kuxinzelelo lwangaphakathi lwemveliso.

Ukuqulunqwa kokwenza uxinzelelo lwangaphakathi ngokusisiseko kubangelwa yi-shrinkage eyahlukeneyo ye-thermal ngexesha lokupholisa. Xa imveliso isenziwa, ukupholisa kwayo kwandisa ngokuthe ngcembe ukusuka phezulu ukuya ngaphakathi, kwaye umgangatho wokuqala uyancipha kwaye unzima, kwaye ngokuthe ngcembe ukuya ngaphakathi. Kule nkqubo, uxinzelelo lwangaphakathi luveliswa ngenxa yokwahlukana kwesantya sokunciphisa.

Xa uxinzelelo lwangaphakathi olushiyekileyo kwicandelo leplastiki liphezulu kunomda we-elastic we-resin, okanye phantsi kokukhukuliseka kwendawo ethile yeekhemikhali, ukuqhekeka kuya kwenzeka kumphezulu wenxalenye yeplastiki. Uphononongo lwe-PC kunye ne-PMMA ye-resin ecacileyo ibonisa ukuba uxinzelelo lwangaphakathi olushiyekileyo kwi-surface layer lunyanzeliswa kwaye i-internal layer is extensions.

Uxinzelelo loxinzelelo lomphezulu luxhomekeke kwimeko yokupholisa komphezulu, kwaye ukubumba okubandayo kwenza i-resin etyhidiweyo iphole ngokukhawuleza, nto leyo eyenza ukuba iimveliso ezibunjiweyo zivelise uxinzelelo oluphezulu lwentsalela yangaphakathi.

Iqondo lokushisa ngundo yeyona meko isisiseko ukulawula uxinzelelo lwangaphakathi. Ukuba iqondo lokushisa lokungunda litshintshile kancinci, uxinzelelo lwangaphakathi olushiyekileyo luya kutshintshwa kakhulu. Ngokuqhelekileyo, uxinzelelo lwangaphakathi olwamkelekileyo lwemveliso nganye kunye ne-resin inomlinganiselo ophantsi wokushisa wokungunda. Xa usenza umgama obhityileyo okanye umgama omde wokuhamba, ubushushu bokubumba kufuneka bube phezulu kunobuncinci bokubumba ngokubanzi.

3. Phucula imveliso warping.

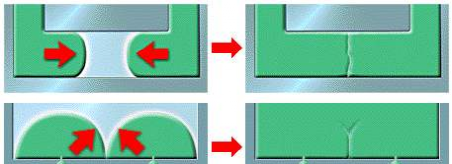

Ukuba uyilo lwenkqubo yokupholisa isikhunta singenangqiqo okanye ukushisa kwesikhunta akulawulwa ngokufanelekileyo, kwaye iindawo zeplastiki azipholile ngokwaneleyo, ziya kubangela ukuba iindawo zeplastiki zidibanise.

Ukulawula ubushushu bomngundo, umahluko weqondo lobushushu phakathi kokubumba okulungileyo kunye nokubumba okubi, undoqo wokubumba kunye nodonga lokubumba, udonga lokubumba kunye nokufakwa kufuneka kunqunywe ngokweempawu zesakhiwo seemveliso, ukuze ulawule. izinga lokupholisa lokucutheka kwenxalenye nganye yokubumba. emva kokudilizwa, iinxalenye zeplastiki zikholisa ukugoba ukuya kwicala lokutsalwa ngobushushu obuphezulu, ukuze kuncitshiswe i-orientation shrinkage umahluko kwaye uthintele iindawo zeplastiki ezijija ngokomthetho wokuqhelaniswa. Kwiingxenye zeplastiki ezinemilo ye-symmetrical ngokupheleleyo kunye nesakhiwo, ukushisa kwe-mold kufuneka kugcinwe ngokufanelekileyo, ukwenzela ukuba ukupholisa kwenxalenye nganye yecandelo leplastiki kufuneka kulinganiswe.

4. Ukuchaphazela i-shrinkage yokubumba imveliso.

Iqondo lokushisa eliphantsi lokungunda likhawulezisa imolekyuli "indawo yokukhenkcela" kwaye inyusa ubukhulu bomaleko onomkhenkce wokunyibilika kwindawo yokubumba, ngelixa ubushushu obuphantsi bokubumba buthintela ukukhula kwekristale, ngaloo ndlela kunciphisa ukubunjwa kweemveliso. Ngokuchasene noko, xa ukushisa kwesikhunta kuphezulu, ukunyibilika kuphola ngokukhawuleza, ixesha lokuphumla lide, inqanaba lokuqhelanisa liphantsi, kwaye kunenzuzo kwi-crystallization, kwaye i-shrinkage yangempela yemveliso inkulu.

5. Ukuchaphazela ukushisa kwe-deformation eshushu yemveliso.

Ngokukodwa kwiiplastiki zekristalline, ukuba imveliso ibunjwe kwiqondo lokushisa eliphantsi lokungunda, i-molecular orientation kunye ne-crystallization zikhenkcezwa ngoko nangoko, kwaye ikhonkco lemolekyuli liya kulungelelaniswa ngokuyinxenye kwaye likhazimliswe kwindawo yobushushu obuphezulu okanye iimeko zokusetyenzwa kwesibini, okwenza ukuba imveliso iguqulwe. okanye ngaphantsi kakhulu kunobushushu be-thermal deformation (HDT) yezinto.

Indlela echanekileyo kukusebenzisa iqondo lokushisa elicetyiswayo elikufutshane nobushushu bayo be-crystallization ukwenza imveliso igxininise ngokupheleleyo kwinqanaba lokubumba inaliti kwaye ugweme i-post-crystallization kunye ne-post-shrinkage kwindawo yokushisa ephezulu.

Ngelizwi, ubushushu bomngundo yenye yezona parameters zolawulo olusisiseko kwinkqubo yokubumba inaliti, kwaye ikwayeyona nto iqwalaselwayo kuyilo lokungunda.

Impembelelo yayo ekubunjweni, ukuqhutyelwa phambili kwesibini kunye nokusetyenziswa kokugqibela kweemveliso ayikwazi ukujongelwa phantsi.

Ixesha lokuposa: 23-12-22