I-polymer porous material yimathiriyeli yepolymer enemibhobho emininzi eyenziwe yigesi esasazwe kwizinto zepolymer.

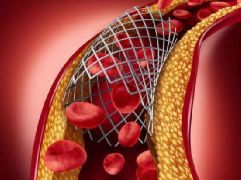

Esi sakhiwo esikhethekileyo se-porous silungile kakhulu ekusetyenzisweni kwezixhobo ezifunxa isandi, ukwahlukana kunye ne-adsorption, ukukhululwa okuqhubekayo kweziyobisi, i-scaffold yamathambo kunye nezinye iinkalo.

Izinto zemveli ze-porous, ezifana ne-polypropylene kunye ne-polyurethane, akulula ukuba zithotywe kwaye zithathe i-petroleum njengezinto eziluhlaza, eziza kubangela ukungcoliseka kwendalo.

Ke ngoko, abantu baqala ukufunda izinto ezinokuboliswa kwimingxuma evulekileyo.

Ukusetyenziswa kwemathiriyeli evulekileyo ye-PLA:

Isixhobo esivulekileyo se-PLA sikwanazo ezinye izinto ezingeloncedo, ezithi zinciphise ukusetyenziswa kwayo kwindawo yemathiriyeli evulekileyo, efana nale:

1. Ubume beCrisp, amandla aphantsi obunzima kunye nokungabikho kwe-elasticity ye-perforated material.

2. Izinga lokuthotywa kancinci.

Ukuba ishiywe emzimbeni ixesha elide njengechiza, inokubangela ukuvuvukala.

3. Khupha amanzi.

Ubudlelwane obuphantsi beeseli, ukuba zenziwe kwithambo lokwenziwa okanye iiseli zescaffold kunzima ukubambelela kwaye zande.

Ukuze kuphuculwe iintsilelo zezinto ezivulekileyo ze-PLA, ukudibanisa, ukuzaliswa, i-copolymerization kunye nezinye iindlela zamkelwe ukuphucula izixhobo ezivulekileyo ze-PLA.

Ezi zilandelayo zizikimu ezininzi zohlengahlengiso zePLA:

I-1.PLA/PCL yokudibanisa ukuguqulwa

I-PCL, okanye i-polycaprolactone, iphinde ibe yinto enokuchithwa kwezinto eziphilayo kunye ne-biocompatibility efanelekileyo, ukuqina kunye namandla okuqina.

Ukudibanisa ne-PLA kunokuphucula ngokufanelekileyo ukomelela kokuqina kwe-PLA.

Abaphandi bafumanisa ukuba iipropati zinokulawulwa ngokulawula umlinganiselo we-PCL kwi-PLA.Xa umlinganiselo we-PLA ukuya kwi-PCL wawuyi-7: 3, amandla e-tensile kunye ne-modulus yezinto eziphathekayo ziphezulu.

Nangona kunjalo, ubunzima buyancipha ngokunyuka kwe-pore diameter.

Izinto ze-PLA/PCL aziyiyo inetyhefu kwaye zinezicelo ezinokuthi zibekho kwi-diameter encinci ye-vascular tissues.

2.PLA/PBAT ukuguqulwa komxube

I-PBAT yimathiriyeli eyonakaliswayo, enokonakala kwe-aliphatic polyester kunye nokuqina kwe-polyester enevumba elimnandi.I-brittleness ye-PLA inokuphuculwa emva kokudibanisa ne-PLA.

Uphando lubonisa ukuba ngokunyuka komxholo we-PBAT, i-porosity yezinto ezivulekileyo ziyancipha (i-porosity iyona nto iphezulu xa umxholo we-PBAT u-20%), kwaye ukunyuka kwe-fracture kwanda.

Okubangela umdla kukuba, nangona ukongezwa kwe-PBAT kunciphisa amandla okuqina e-PLA, amandla okuqina e-PLA ayanda xa icutshungulwa kwizinto ezivulekileyo.

3.PLA/PBS ukudibanisa ukuguqulwa

I-PBS yi-biodegradable material, eneempawu ezilungileyo zoomatshini, ukumelana nobushushu obugqwesileyo, ukuguquguquka kunye nokukwazi ukucubungula, kwaye isondele kakhulu kwi-PP kunye ne-ABS.

Ukudibanisa i-PBS kunye ne-PLA kunokuphucula i-brittleness kunye nokuqhubekeka kwe-PLA.

Ngokophando, xa ubuninzi be-PLA: i-PBS yayingu-8: 2, umphumo obanzi wawungcono kakhulu;ukuba i-PBS yongezwa ngokugqithisileyo, i-porosity yezinto ezivulekileyo ziya kuncitshiswa.

I-4.PLA / iglasi ye-BIOactive (BG) yokuzalisa ukuguqulwa

Njengezinto zeglasi ezisebenzayo, i-BG ikakhulu yenziwe ngesilicon sodium calcium phosphorus oxide, enokuphucula iimpawu zoomatshini kunye ne-bioactivity ye-PLA.

Ngokunyuka komxholo we-BG, i-tensile modulus yezinto ezivulekileyo zomngxuma zonyuka, kodwa amandla okuqina kunye nobude bekhefu behla.

Xa umxholo we-BG uyi-10%, i-porosity yezinto ezivulekileyo ziphezulu (87.3%).

Xa umxholo we-BG ufikelela kwi-20%, amandla oxinzelelo lwe-composite aphezulu.

Ngaphezu koko, i-PLA/BG i-composite ye-porous material ingafaka umaleko we-apatite we-osteoid kumphezulu nangaphakathi kulwelo olulinganisiweyo lomzimba, olunokubangela ukuvuselelwa kwamathambo.Ngoko ke, i-PLA / BG inamandla okusetyenziswa kwizinto eziphathekayo zethambo.

Ixesha lokuposa: 14-01-22