Kwinkqubo yokuveliswa kwemveliso, i-dents yemveliso kunye ne-pores yizona ziganeko ezimbi kakhulu. Iplastiki etofelwe kukungunda iyancipha umthamo njengoko iphola. Umphezulu uba lukhuni kuqala xa uphola kwangethuba, kwaye amaqamza enza ngaphakathi.

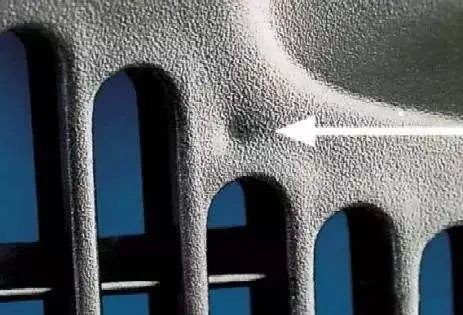

I-indentation yinxenye yokupholisa kancinane yeqamza kwicala lokucutheka komphezulu we-concave; I-stoma ebizwa ngokuba yi-stoma ibhekisela kwizinto ezibonakalayo kwi-mold ziqina ukusuka kumphezulu, okungekho ngokwaneleyo kumthamo opheleleyo we-mold. Ngenxa yesi sizathu, imingxuma kwi-vacuum state yenziwa, eyenzeka ngokubanzi kwiindawo ezishinyeneyo zemveliso kunye nechweba lokuzalisa.

Iimathiriyeli ezinokuncipha okuphezulu nazo ziqhelekile ekungeneni. Xa utshintsha imeko yokubumba ukuphelisa i-indentation, imeko yokumisela kufuneka ibekwe kwicala lokunciphisa. Oko kukuthi, ubushushu bomngundo kunye nobushushu bomgqomo buyancipha, uxinzelelo lwenaliti luyenyuka, kodwa kufuneka kuqatshelwe ukuba oku kunokubangela uxinzelelo lwangaphakathi olushiyekileyo.

Ngenxa yokuba i-indentation ayibonakali, ngoko ayichaphazeli ukubonakala kwenkqubo kwi-mold ibe yi-corrosion, njenge-striated, granular njalo njalo.

Ukunciphisa iqondo lobushushu lokufa ukunciphisa ukugqiba kusebenza kwakhona ukuba izinto zokubumba ziyi-HIPS ye-polystyrene enganyangekiyo (uhlobo lwe-polystyrene PS). Kodwa xa kukho isibotho kwezi ndlela, kuba nzima ukuyilungisa loo mveliso ikhazimlisiweyo.

Iimveliso ezicacileyo ezinemingxuma yomoya ziyingxaki, iimveliso ze-opaque ezinemingxuma yomoya ayinayo imiqobo yokusebenzisa kwaye akufanele ibonakale kwimveliso.

Ngenxa yamanzi kunye neenguqu eziveliswa yi-stomata, ngokubanzi zisasazeka kuzo zonke iindawo zemveliso, ukumila kwe-stomata kuncinci.

Okokuqala, isisombululo

Kwangoko: yonyusa uxinzelelo lwenaliti, yandisa uxinzelelo lwenaliti yokubamba ixesha, ukunciphisa iqondo lobushushu lomphanda kunye nobushushu bokungunda, ukufuma kunye nokuguquguquka okubangelwa zizinto eziphathekayo kufuneka zome ngokupheleleyo, endaweni yokupholisa ngenkani.

Ixesha elifutshane: Gcwalisa umphetho ophezulu apho i-indentation yenziwe. Apho isibobo senziwe khona, i-material iyaqina njengoko idlula kwindawo emxinwa.

Ixesha elide: umehluko wobunzima beemveliso zoyilo kufuneka ugwenywe ngokupheleleyo. Kulula ukuvelisa ukuqiniswa kwe-dent, imilo emide kunye nemxinwa kufuneka ibe mfutshane kangangoko. Kufuneka yandise isango, umjelo oyintloko, i-shunt, umngxuma wombhobho. Ukukhupha okuphuculweyo.

Okwesibini, imiba yereferensi

I-1 yokubumba i-shrinkage ye-indentation enkulu yezinto nayo inkulu, njenge-polyethylene PE, i-polypropylene PP, nangona nje ukuqiniswa okuncinci, kuya kuvelisa i-indentation.

| Izinto eziphathekayo | Izinga lokushwabana komngundo |

| PS | 0.002 ~ 0.006 |

| PP | 0.01 ~ 0.02 |

| PE | 0.02 ~ 0.05 |

2. Xa iqondo lokushisa lincitshiswe ukuba lingabikho, ukuba izinto eziphathekayo kwi-mold cavity zisaphantsi koxinzelelo, kufuneka kuthathelwe ingqalelo ukuba akukho mazinyo aya kuveliswa. Uxinzelelo lwezinto ezijikeleze isikhunta kwi-mold, oko kukuthi, uxinzelelo lwe-static, alukho kuyo yonke indawo.

Ngokusondeleyo kwisango lecandelo loxinzelelo liphezulu, ukuba i-edge ebanzi yezinto eziphathekayo, ngenxa yokudluliselwa koxinzelelo kuzo zonke iikona, kufuphi nesango kwaye kude nesango lokuhlukana koxinzelelo kunye noxinzelelo olupheleleyo xa kuthelekiswa nentlukwano encinci ayiyi ukuvelisa izibonda, kananjalo abanakufumana mveliso yoxinzelelo lwangaphakathi olushiyekileyo.

Xa ezinye izinto zigeleza kwindawo enzima, kukho uxinzelelo oluphezulu kule ndawo, kwaye uxinzelelo luyancipha kwezinye iindawo, okubangelwa yi-dents. Le nxalenye ye-residu ephezulu yoxinzelelo luxinzelelo lwangaphakathi lwemveliso nayo inkulu. Kwimeko efanelekileyo, ubumanzi bezinto eziphathekayo bungcono xa ubushushu bezinto eziphathekayo bunyuka kunye nobushushu bokufa, kunye nenaliti kwimeko yoxinzelelo lwe-static nayo iyancipha.

3. Ekutshintsheni kweemeko zokubumba, ukudibanisa kweqondo lokushisa, uxinzelelo kunye nexesha kufuneka lwenziwe kwangaphambili kwetafile, ukuze ukwazi iziphumo. Okokuqala, xa ixesha liba lide kakhulu, kulula ukwazi lonke utshintsho oluncinci kuxinzelelo. Kufuneka kuqatshelwe ukuba iziphumo ezifunyenweyo xa utshintsho lweqondo lokushisa kufuneka luveliswe emva kwempahla yokutofa kwaye emva kokuhla kweqondo lokushisa.

4. Ukumisela izizathu ezibangelwa yi-pores, nje ukuba ukubonwa kwe-bubble yeemveliso zeplastiki kwi-mold ngokukhawuleza okanye emva kokupholisa, ukuba xa isikhunta sihamba ngokukhawuleza, ininzi yinkinga yezinto eziphathekayo, ukuba emva kokupholisa. , yeyomngundo okanye iimeko zokutofa.

Ixesha lokuposa: 03-11-22