Iplastiki kufuneka yomiswe kakuhle phambi kokuba yenziwe. Emva kokuba izinto eziqulethwe ngamanzi zingene kumgodi wokungunda, umphezulu wamacandelo uya kubonakala isiphene sesash yesilivere, kwaye isenzeko sokubola kwamanzi siya kwenzeka kwiqondo lokushisa eliphezulu, okukhokelela ekuwohlokeni kwezinto. Ngoko ke, izinto eziphathekayo kufuneka zenziwe kwangaphambili ngaphambi kokwenza, ukwenzela ukuba izinto eziphathekayo zikwazi ukugcina umswakama ofanelekileyo.

Kubalingane bokungena kwinqanaba, le nkcukacha yokubumba ipharamitha yenaliti yindlela elungileyo yokukhumbula, kwiingcali, ukuthwala, ukukhumbula lula, kulula kwaye kusebenza kakuhle.

1. Uxinzelelo lwesitofu

Uxinzelelo lwe-injection lunikezelwa yinkqubo ye-hydraulic yomshini wokubumba inaliti. Uxinzelelo lwe-cylinder ye-hydraulic idluliselwa kwi-injection inyibilika nge-screw yomshini wokubumba inaliti. Iqhutywa luxinzelelo, inyibilika yeplastiki ingena kumjelo oyintloko wokubumba ukusuka kwi-nozzle kwaye ifakwe kwi-mold cavity ngomlomo ojikelezayo.

2. Ixesha lokutofa

Ixesha lokubumba lenaliti elifanelekileyo liluncedo ekugcwaliseni inyibiliko yeplastiki, ehlala imalunga ne-1/10 yexesha lokupholisa. Ufuna ukucinezela imathiriyeli yokutofa eyahlukileyo ukwenza isigqibo.

3. Iqondo lokushisa lokutofa

Ubushushu be-injection yinto ebalulekileyo echaphazela uxinzelelo lwenaliti, ukushisa kwenaliti kufuneka kulawulwe kuluhlu olufanelekileyo, ubushushu obuphantsi, i-plasticization engalunganga yezinto ezikrwada; Izinto ezikrwada zibola ngokulula kwiqondo lobushushu eliphezulu kakhulu. Ngoko ulawulo lobushushu yimfuneko yenkosi enamava kulawulo olufanelekileyo.

4. Ukubamba uxinzelelo kunye nexesha

Ekupheleni kwesitofu sokubumba, i-screw iyayeka ukujikeleza kwaye iqhubela phambili, ingena kwinqanaba lokubamba uxinzelelo. Kwinkqubo yokubamba uxinzelelo, i-nozzle idibanisa ngokuqhubekayo i-raw material inyibilika kwi-cavity ukuqinisekisa ukunyaniseka kwemveliso emva kokubumba. Ukubamba uxinzelelo ngokuqhelekileyo kuzaliswe ngoxinzelelo oluphezulu lwe-80% okanye kunjalo, ngokweemfuno zezinto ezibonakalayo kunye neemveliso.

5. Uxinzelelo lwangasemva

Uxinzelelo lwangasemva lubhekiselele kuxinzelelo oluza koyiswa xa isikrufu sibuyela umva kwimpahla yokugcina. Uxinzelelo oluphezulu lwangasemva lunceda ukusasazeka kombala kunye nokunyibilika kweplastiki.

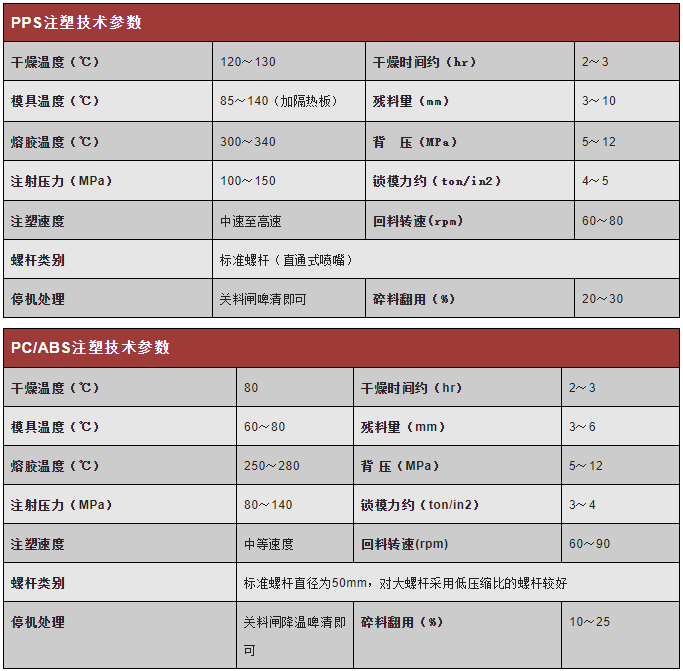

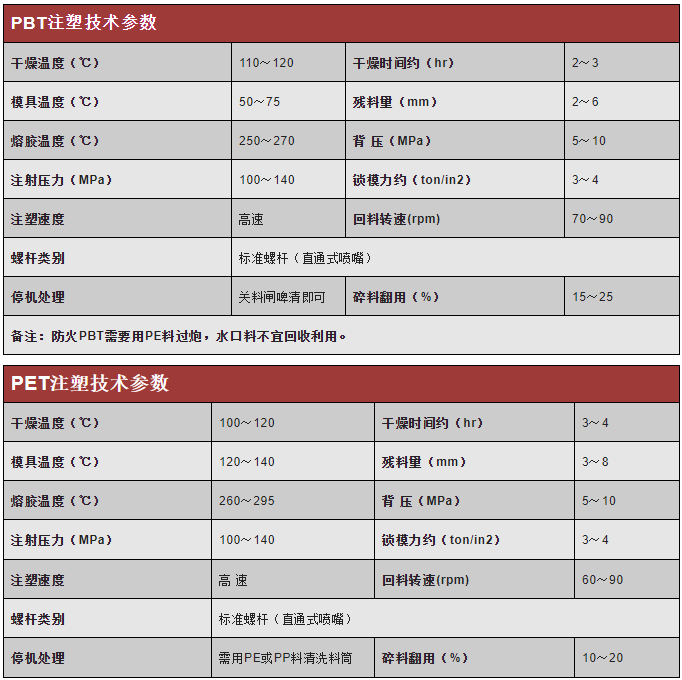

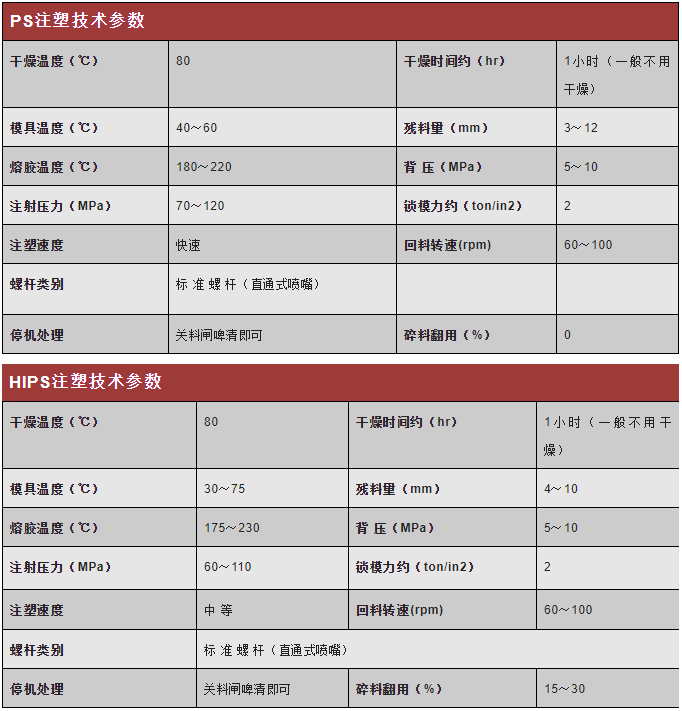

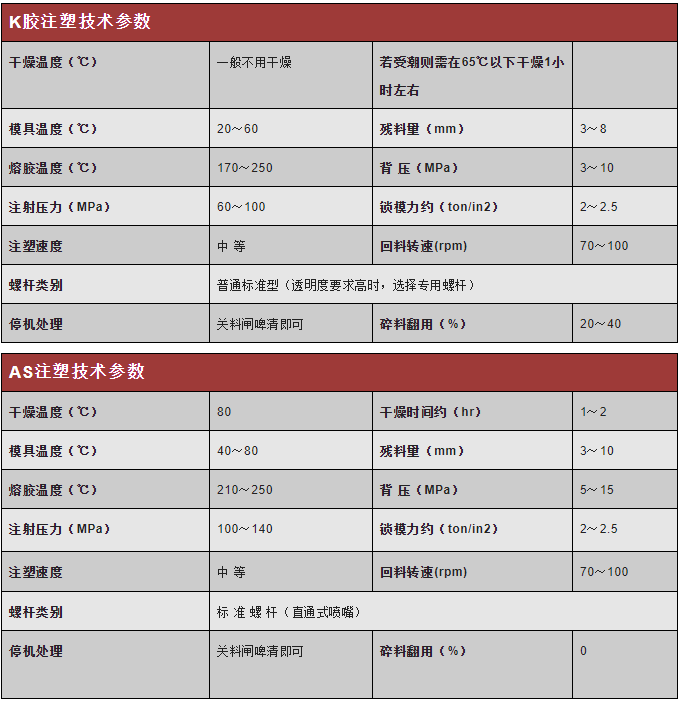

Iiparameters zokubumba ze-injection yeeplastiki eziqhelekileyo

Ixesha lokuthumela: 29-06-22